I love to blow things up. The best opportunity I get every year is Fourth of July. We put on a great fireworks show every year. We use an electronic ignition system and this year we fired off 244 two inch mortars and about 100 cake items. Our current system has 32 channels, which means we have to fuse together multiple items for each channel and then “hope” the fusing works and we have estimated the timing correctly.

Next year will be different. We are moving to a new system which has 144 channels and we are getting new mortar tube racks and adding tubes to bring our total to 324. The new control system uses a distributed set of controllers that need to be in cases to protect them from the elements and the fall out from the fireworks.

I could buy cases, but I could also 3D print them. Or more accurately, have the sons of one of my executive team members print them for me. I have worked with these young men off and on over the years on engineering fair projects and side projects. They are very smart, very curious, and very self motivated. One of them recently built a flame thrower, so they also share a love for blowing up and or burning things.

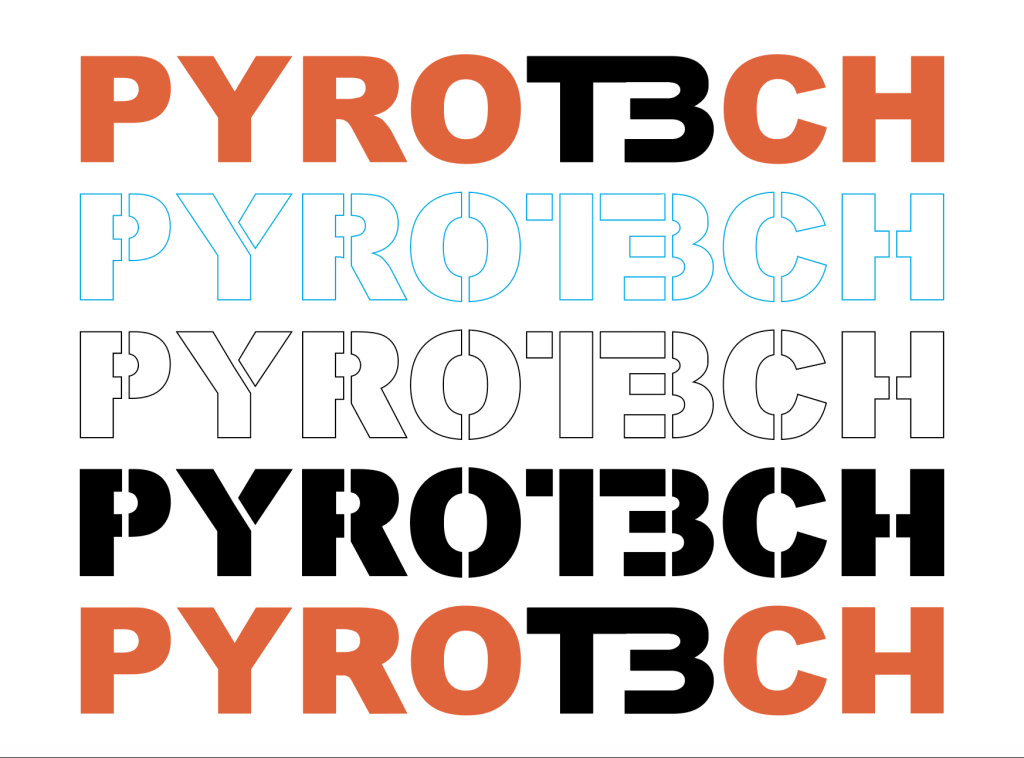

If you’re going to make your own stuff, you should have a brand and go all the way. When I printed out the word “PYROTECH” I noticed the TE which I could make a T3 and the word would still be readable. It’s actually amazing how adaptive our minds are in recognizing familiar words even if they are messed up.

Once I had a word mark I realized I could add this to the mortar racks and the fuel mine tubes easily with a stencil. We would paint everything black and then stencil the word mark on in orange. That meant I needed to create a stencil which requires cutting the letters into sections so the insides are anchored and there are no parts that can lift and allow paint to get underneath.

While creating the stencil I ended up adjusting the original because I liked some of the letter form changes that made the stencil look and work better:

Then I messed withe it some more and added a firework element: